TT Green and TT Chain Use Cases

Smart Farming HK Aquaponics System

Hong Kong’s First Food Waste Recycle And Aquaponics System In Smart Farming

Food Waste recycle to fish feed

Accredited Fish Farm Scheme

1. Food waste

2. Recycle Process

3. Fish Feed

4. Feed fish in Smart Farming

5. Real-time tank data collected

6. Fish selling with QR code

Carbon Neutral Label for Recycled Sunglasses

BD8, A HK-based Plastic Recycling Company

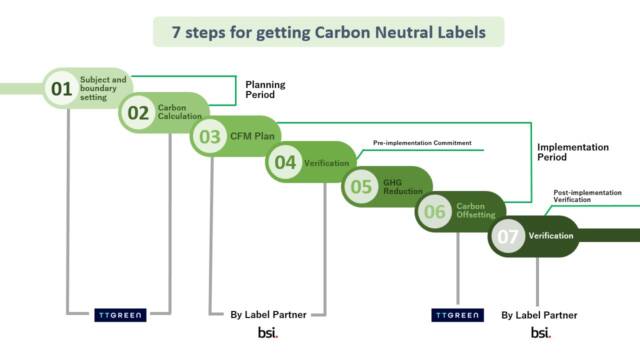

Achieving Carbon Neutral on TT Green

With the help of TT Green’s ESG ecosystem, DB8 seamlessly completed the whole journey of obtaining carbon-neutral labels on one single platform, TT Green. First, BD8 defines its boundaries (Scope 1,2,3) on TT Green and calculates the carbon emission with TT Green’s Global Carbon Footprint Calculator. After that, TT Green purchased suitable carbon credits for BD8 and offset their unavoidable carbon emission. The Carbon Neutral Label Certifier, who is also an official partner of TT Green, then leverages the trusted ESG data on TT Green to go through the assessment procedures and issue the Carbon Neutral Label to BD8.

Genesis Mongolian Cashmere

Applying TT Chain in apparel industry

TT Chain in the Apparel Industry – Mongolian Cashmere

1. Farmer:

Inputs data including the origin, and video of shearing. This counts as a new ‘lot’ added to the system and verification code is produced.

2. Inspector:

Use farmers code to verify information and the update wool lot in the system to add certification. Unique ID is generated and attached to the shipment.

3. Yarn manufacturers:

Use the ID to retrieve and verify lot details. After processing and the addition of any further needed data, the system will generate a new ID to be applied to the resulting packages.

4. Garment manufacturer:

Receiver scans the ID to retrieve and verify package details and then updates the system to reflect of the package has arrived as expected. When completed, the system creates a new ID to be applied to the resulting products.

100% traceable Canadian Beef

Beef industry

TT Chain in the Food Industry – Beef in conjunction with TrustBIX

1. Farmer and Vet:

2. Abattoir and packaging:

The cow will then be packaged accordingly and a new code will be added to the product.

3. Distributer:

The distributer will then use the appropriate transportation to ship its products.

4. Retailer:

The retailer will add additional information such as recipes and wine suggestions.

5. Store:

Has full transparency on the delivery time and able to adapt accordingly. Can alter promotions and orders.

6. Consumer:

Consumers can simply scan a QR code attached on the packaging on the beef product. From there, the consumer can then understand the origin, overall health of the cow and many more in order empower informed decision making for consumers.

Social Enterprise: Tea Bags

Social Enterprise: Tea Bags

The program aims to achieve 3 goals:

Provide environmental education opportunities (Clean & Green the School)

Provide learning opportunities about cultural knowledge (Traditional Herbal Medicine)

Support school operation (Supplemental income by growing herbal plants)

With TT Chain’s platform the final consumer would be able to trace all the production stages and knowing who they are really helping when they made a purchase, where they are taking a part in this wonderful programme with about 4,000 Cambodian partners and students.

“SALASUSU” Eco Bags

“SALASUSU” Eco Bags

By scanning the QR code on SALASUSU’s product, consumer will be able to trace all the information and history of the products, and most importantly – who is making your product. Photos of the worker will be shown and customer can tell who is doing what – from cutting, sewing and packaging.